Description

We offer comprehensive services for the design, engineering, and supply of LPG storage tank terminals. Our plants are customizable to meet clients’ specific requirements for different filling capacities and levels of automation.

Key components of our standard installations include:

- LPG storage tanks equipped with ladder gantries, platforms, and safety fittings

- LPG pumps and compressors

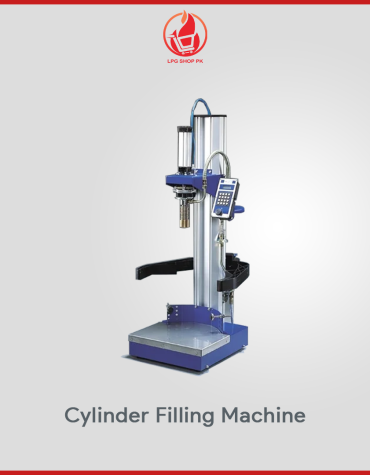

- Electronic LPG filling machines with options for manual operation or carousel systems. These machines feature automatic cylinder centralization, inlet and outlet automation, individual PLCs for each filling post, and seamless integration with the central unit. Additional accessories ensure accurate cylinder filling and monitoring of quality, weight, repeatability, productivity, and security.

- Inline electronic check scales with weight correction units and conveyors

- Purging units and evacuation systems

- Pneumatic operating systems

- Safety fittings comprising remote-operated valves, mass flow meters, pressure transmitters/switches, pop valves, gauges, high-level cutoff and level gauges, gas leak detectors, and mass flow meters.

| VESSEL SPECIFICATION | |

| Design code with calculation | ASME Sec VIII Div I |

| LPG Code | NFPA 58 |

| Design Pressure | 250 Psi |

| Test pressure | 325 Psi |

| Design Temperature | -20’C ~ 66’C |

| Specific Gravity of LPG | 0.55 |

| LPG Capacity | 50 MT @ 85% |

| Water Capacity | 107272 Ltr |

| Vapor Space | 15% |

| Shell Thickness | 25mm |

| Dish Thickness | 14mm |

| Reinforcement Pads | MS |

| Nozzles Flanges | A-105 |

| Attachments | HR-235 |

| Lifting Lugs | HR-235 |

| Fittings | A-234 |

| Valve (inlet/outlet/Vapor) | 3 Connection ~ Fitted |

| Gauges (Pressure/Temperature) | 2 Connection ~ Fitted |

| Roto gauge | Fitted |

| PRV Connection | 01 No. – Fitted |

| Manhole | 18 Inch – Fitted |

| Gasket | Spiral wound, |

| VESSEL DIMENSION | |

| Internal Dia | 3790mm (12’-5”) |

| Length (T/T) | 7000mm (22’-11”) |

| Overall Length | 10818 mm (35’-6”) |

| Shell Weight Approx | 27000kg (Including Connections and fittings) |

| TESTING | |

| DPT | 100% |

| TOFT/RT | 100% |

| Hydro testing | Yes @ 325 Psig |

| PLATE FARM DETAILS | Scope | |

| Walk way | MS Checked plate 3mm | HSE |

| Plate farm | Fabricated with angle. Pipe | HSE |

| Ladder | Fabricated with angle, pipe and MS checked plate foot steps | HSE |

| ACCESSORY DETAILS | Scope | |

| Roto Gauge | Dia 1’’ = 01 No.

(Rego USA) Mounted on Shell for Dia 100’’ -143’’ |

Buyer |

| Temperature gauge | 01 No.

(Imported/Wika China) Size 2.5’’, conn. ¼’’ NPT #6000 Scale Range -30’C to 85 C Dial Size |

Buyer |

| Pressure Gauge | 01No.

(Imported/ Wika China) Psig Dial Size 2.5’’, conn. ¼’’ #6000 Scale Range 0 to 500 Psig -Scale 5 |

Buyer |

| Pressure Relief Valve | Connection Dia 4’’ Multiport M NPT = 01 No.

(Rego USA) Internal Pop Action start to Discharge 250 Psig |

Buyer |

| Ball Valve (For Inlet) | Dia 2’’ Flanged type Class #300 = 01 No.

Design STD: API608, Test STD: API598, 5.0 Mpa, 300 lb (Zhejiang Yu China) |

Buyer |

| Ball Valve (For Outlet) | Dia 3’’ Flanged type Class #300 = 01 No.

Design STD: API608, Test STD: API598, 5.0 Mpa, 300 lb (Zhejiang Yu China) |

Buyer |

| Ball Valve (For Vapor) | Dia 2’’ Flanged type Class #300 = 01 No.

Design STD: API608, Test STD: API598, 5.0 Mpa, 300 lb (Zhejiang Yu China) |

Buyer |

| INTERNAL VALVES | ||

| Vapor Return | Excess Flow Valve 2’’ NPT = 01No.

Rego USA (A 3500 P4) |

Buyer |

| LPG Inlet | Back Check Valve 2’’ NPT = 01No.

Rego USA (A 3400 L4) |

Buyer |

| LPG Outlet | 3’’ Internal Valve with remote Lever = 01No.

Rego USA (A3213RA 3200L + 3200C) |

Buyer |

| PAINT | |

| Power Brushing | Yes |

| Steel Putting | Yes |

| Primer Base Coating | Yes |

| Buyer Scope of Work | Loading, Unloading and all civil work at site |

| Delivery | At the time of order confirmation | ||

| Payment Schedule | Advance 60% at the time of confirmation of order, 30% at the time of fitup, 10% on delivery of each tank. | ||

| Quotation Validity | 01 day | ||

IMPORTANT NOTE: –

To maintain Transport Discipline and reduce accidents, it is necessary to read and follow safety instructions.

According to NFPA 58 (National Fire Protection Association), it is recommended to install the Safety Valves e.g Internal/Excess flow/Back check valves on an inlet, outlet and vapor connections.

So as per standard, we have attached the safety valve connection fitting, to allow tank operator must install the equipment. In the case of ignorance, our company will not be responsible for any disaster. Meanwhile, we are giving services to Install and calibrate the Safety Valves with the collaboration of OGRA approved third parties.

Reviews

There are no reviews yet.