Description

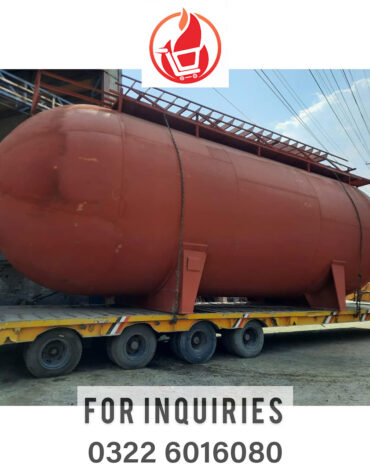

| VESSEL SPECIFICATION | |

| Design code with calculation | ASME Sec VIII Div I |

| LPG Code | NFPA 58 |

| Design Pressure | 250 Psi |

| Test pressure | 325 Psi |

| Design Temperature | -20’C ~ 66’C |

| Specific Gravity of LPG | 0.55 |

| LPG Capacity | 10 MT @ 100% |

| Water Capacity | 18181 Ltr |

| Vapor Space | 0% |

| Shell Thickness | 16mm ~MS A516 GR70 / Eqv. |

| Dish Thickness | 10mm ~ MS A516 GR70 / Eqv. |

| Reinforcement Pads | MS A516 GR70 / Eqv. |

| Nozzles Flanges | Eqv. A-105 |

| Nozzles Pipes | Seamless Type Eqv. A-106 |

| Attachments | Eqv. HR-235 |

| Beam | Eqv. HR-235 |

| Lifting Lugs | Eqv. HR-235 |

| Fittings | Eq. A-234 |

| Valve (inlet/outlet/Vapor) | 3 Connection ~ Fitted |

| Gauges (Pressure/Temperature) | 2 Connection ~ Fitted |

| Needle Valve | Fitted |

| Roto gauge | Fitted |

| PRV Connection | 01 No. – Fitted |

| Manhole | 16 Inch – Fitted |

| Gasket | Spiral wound, SS304/Eqv. |

| PVC Cone | 02No |

| Fire extinguisher | 02No |

| VESSEL DIMENSION | |

| Internal Dia | 2394mm (7’-10”) |

| Length (T/T) | 2500mm (8’-2”) |

| Overall Length | 4914 mm (16’-1”) |

| Shell Weight Approx | 3840kg (Including Connections and fittings) |

| TESTING | |

| DPT | 100% |

| TOFT/RT | 100% |

| Hydro testing | Yes @ 350 Psig |

| STRUCTURE DETAILS | Scope | |

| Valve Box | Fitted, 3mm Window Type | HSE |

| Tools Box | Fitted, 3mm Window Type | HSE |

| Protection Fence | Fitted with extra Luggage Space | HSE |

| Bumper | Fitted- 4mm with Extra Tool Box | HSE |

| Mudguard | 1 set Fitted – 3mm corrugated type | HSE |

| Ladder | Fitted – Made with Round Bar/ Folding Type | HSE |

| U-Beam, I-Beam | Eqv. HR-235 | HSE |

| EQUIPMENT AND ACCESSORIES DETAIL | Scope | |

| Roto Gauge | Dia 1’’ = 01 No.

(Rego USA) Mounted on Shell for Dia 100’’ -143’’ |

HSE |

| Temperature gauge | 01 No.

(Imported/Wika China) Size 2.5’’, conn. ¼’’ NPT #6000 Scale Range -30’C to 85 C Dial Size |

HSE |

| Pressure Gauge | 01No.

(Imported/ Wika China) Psig Dial Size 2.5’’, conn. ¼’’ #6000 Scale Range 0 to 500 Psig -Scale 5 |

HSE |

| Pressure Relief Valve | Connection Dia 2’’ M NPT = 01 No.

(Rego USA) Internal Pop Action start to Discharge 250 Psig |

HSE |

| Ball Valve | Dia 2’’ Flanged type Class #300 = 3 No.

Design STD: API608, Test STD: API598, 5.0 Mpa, 300 lb (Zhejiang Yu China) |

HSE |

| Needle Valve | SS Type Dia ¼’’ = 01 No. | HSE |

| Strainer (for LPG Pump) | Dia 2” Class 300 (Rego) | HSE |

| PTO Driven | PTO driven LPG pump (according to chassis requirement) | HSE |

| Electric Driven | Electric driven system with 5hp motor | N/A

Optional |

| LPG Flow meter | Flange type-Proline Promass E200 (CORIOLIS FLOW METER) | N/A

Optional |

| Expansion Joint for LPG Pump | Log10” = 01No | HSE |

| Expansion joint for Hose Reel | Log10” = 01No | HSE |

| Hose Pipe for vapor | 1” LPG hose pipe for hose reel = 60ft with 2” ANSI Flange | HSE |

| Hose pipe for outlet | 1.25 LPG hose pipe for hose reel = 60ft with 2” ANSI Flagne | HSE |

| Pneumatic Shut down System | N/A | N/A

Optional |

| LPG Pipe line | LPG piping networking (according to diagram) | HSE |

| INTERNAL VALVES | ||

| Vapor Return | Excess Flow Valve 2’’ NPT = 01No.

Rego USA (A 3500 P4) |

HSE |

| LPG Inlet | Back Check Valve 2’’ NPT = 01No.

Rego USA (A 3400 L4) |

HSE |

| LPG Outlet | 2’’ Internal Valve with remote Lever = 01No.

Rego USA (A3213RA 3200L + 3200C) |

HSE |

| Electric | |

| Electric wiring | Yes |

| Bumper Lights | 01 set, Brand Sheldo (China) |

| Hazard Lights | 01 set, Brand Sheldo (China) |

| Indicators | 01 Set, Brand Sheldo (China) |

| Show lights | 4 pairs, Brand Sheldo (China) |

| PAINT | |

| Power Brushing | Yes |

| Steel Putting | Yes |

| Primer Base Coating | Yes |

| Enamel Coating | Double Coated, Complete Finishing |

| Featured Design | Yes, As per requirement |

| Safety Label | Yes |

| Installation Service | Fit up on chassis and installation of above mentioned instruments and equipments | HSE |

| Buyer Scope of Work | Providing of chassis/Prime Over |

| Delivery | Within 1 Month |

| Payment Schedule | Advance 70% at the time of confirmation of order, 30% on delivery |

*Price stability will be conditional with basic steel and energy prices*

IMPORTANT NOTE: –

To maintain Transport Discipline and reduce accidents, it is necessary to read and follow safety instructions.

According to NFPA 58 (National Fire Protection Association), it is recommended to install the Safety Valves e.g Internal/Excess flow/Backcheck valves on an inlet, outlet and vapour connections.

So as per standard, we have attached the safety valve connection fitting, to allow tank operator must install the equipment. In the case of ignorance, our company will not be responsible for any disaster. Meanwhile, we are giving services to Install and calibrate the Safety Valves with the collaboration of OGRA approved third parties.

Reviews

There are no reviews yet.