How much does an LPG plant cost in Pakistan?

If you’re considering setting up an LPG plant in Pakistan, one of the crucial factors you need to consider is the cost involved. The cost of establishing an LPG (liquefied petroleum gas) plant can vary depending on several key factors, including the plant’s capacity, technology, infrastructure requirements, and regulatory compliance. In this comprehensive guide, we will delve into the various components that contribute to the cost of an LPG plant in Pakistan.

- Plant Capacity and Technology

The capacity of an LPG plant is a significant determinant of its cost. Higher-capacity plants require more extensive infrastructure and equipment, resulting in increased investment. Additionally, the technology employed in the plant plays a vital role in determining its efficiency, productivity, and overall cost. Advanced technological solutions may contribute to a higher initial investment but can result in long-term operational savings and enhanced productivity.

- Infrastructure and Construction

The infrastructure and construction expenses associated with setting up an LPG plant are crucial cost factors. This includes acquiring or leasing land, constructing storage facilities, installing pipelines, and establishing administrative and operational buildings. The location of the plant also influences the infrastructure costs, as transportation and logistical aspects need to be considered.

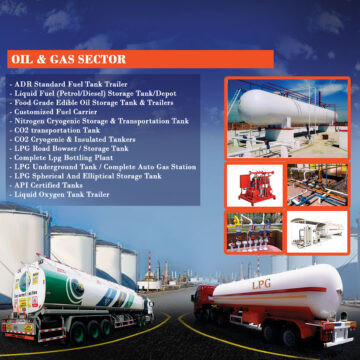

- Equipment and Machinery

Investing in the right equipment and machinery is crucial for the successful operation of an LPG plant. The cost of equipment depends on various factors such as plant capacity, technological requirements, safety standards, and regulatory compliance. Key equipment includes storage tanks, vaporizers, pumps, compressors, safety systems, and filling stations. Opting for high-quality, certified equipment ensures reliability, safety, and long-term cost efficiency.

- Regulatory Compliance

Complying with the regulatory requirements and safety standards set by local authorities is paramount when establishing an LPG plant. This involves obtaining licenses, permits, and certifications, as well as implementing safety measures and conducting regular inspections. Compliance costs can vary depending on the complexity of regulations and the level of adherence required.

- Operational Costs

In addition to the initial investment, it is essential to consider the ongoing operational costs of an LPG plant. These costs include raw material procurement, transportation, employee salaries, maintenance, utility bills, insurance, and other miscellaneous expenses. Proper budgeting and financial planning are crucial to ensure the smooth operation and sustainability of the plant.

- Market Dynamics and Price Fluctuations

The cost of an LPG plant is also influenced by market dynamics and price fluctuations. Factors such as the availability and cost of raw materials, market demand, competition, and government policies can impact the profitability and return on investment. It is advisable to conduct a thorough market analysis and feasibility study before venturing into the LPG business to assess potential risks and rewards.

Conclusion

Establishing an LPG plant in Pakistan involves a substantial initial investment and ongoing operational costs. The total cost depends on various factors, including plant capacity, technology, infrastructure requirements, regulatory compliance, and market dynamics. Conducting a detailed feasibility study, collaborating with experienced professionals, and leveraging industry best practices can help optimize costs and maximize the plant’s efficiency and profitability.

Remember, thorough research, careful planning, and adherence to safety standards and regulations are crucial for the successful and sustainable operation of an LPG plant in Pakistan.

Due to Economy crises raw material price change day by day if you want to quotation of any size of complete LPG plant please WhatsApp +92 322 6016080